Zone2 approved HMI

Saturday, 14 July 2012

Friday, 13 July 2012

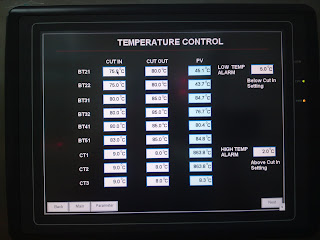

HMI အား iphone မွထိန္းခ်ဳပ္ေမာင္းႏွင္ျခင္း

Weinview HMI ဧ။္ i နဲ႔ X series တြင္ VNC server ( Virtual Network Computing ) ပါ၀င္လာသည္။ ယင္း VNC ကိုအသံုးျပဳျပီး remote machine မွ HMI အားထိန္းခ်ဳပ္ေမာင္းႏွင္ႏိုင္သည္။ သို႔ရာတြင္ HMI ႏွင့္ Remote Machine ( iphone or PC ) သည္ Ethernet LAN network တစ္ခုအတြင္းတြင္ရိွရမည္။HMI software နဲ႔ VNC viewer အား free download လုပ္ႏိုင္သည္။

အဆင့္၁။ HMI တြင္ VNC server အားဖြင့္ျပီး password ေပးပါ။

အဆင့္၂။ java IE သို႔မဟုတ္ VNC viewer ကို remote machine ( iphone/PC ) သို႔ install လုပ္ပါ။

အဆင့္၃။ Install လုပ္ျပီးေနာက္ ေအာက္ပါအတိုင္း HMI ဧ။္ ip နဲ႔ password ရုိက္ထည္႔လိုက္ပါက HMI အား iphone/PC ေပၚမွလွမ္းျမင္ရျပီး HMI အားထိန္းခ်ဳပ္ေမာင္းႏွင္ႏိုင္ျပီျဖစ္သည္။

တစ္ၾကိမ္တြင္ user တစ္ဦးသာ HMI အား access လုပ္ႏိုင္မည္။

VNC server အား ၁ နာရီႀကာ အသံုးမျပဳဘဲ ထားပါက auto log out ျဖစ္သြားမည္။

Download Link: www.weintek.com

http://www.realvnc.com

Saturday, 7 July 2012

Thursday, 5 July 2012

RESISTANCE TEMPERATURE DETECTION ( RTD )

One of Japanese customer asked for ClassA RTD at one of the meeting. I don't know what class A is. After meeting, I went online and look for ClassA type RTD. Below are some information I find out about ClassA RTD

IEC60751အရ Thin Film RTD ဧ။္ tolerance အေပၚမူတည္ျပီး Class ၃ မိ်ဳးခဲြျခားထားသည္။

1. Class AA (Formerly 1/3B) = ±(0.1+0.0017*t)°C or 100.00 ± 0.04Ω at 0°C

2. Class A = ±(0.15+0.002*t)°C or 100.00 ± 0.06Ω at 0°C

3. Class B = ±(0.3+0.005*t)°C or 100.00 ± 0.12Ω at 0°C

ထို႔အျပင္ IEC တြင္မပါ၀င္ေသာအမိ်ဳးအစားတခုရိွေသးသည္။

Class 1/10B = ±1/10 (0.3+0.005*t)°C or 100.00 ± 0.012Ω at 0°C

ဥပမာ ClassA ဧ။္ tolerance သည္ Temp 100'C တြင္±0.35'C ရိွသည္။

အသံုးျပဳမည့္ေနရာကို လိုက္ျပီးသင့္ေတာ္ေသာ Class ကိုေရြးခ်ယ္ပါ။

One of Japanese customer asked for ClassA RTD at one of the meeting. I don't know what class A is. After meeting, I went online and look for ClassA type RTD. Below are some information I find out about ClassA RTD

IEC60751အရ Thin Film RTD ဧ။္ tolerance အေပၚမူတည္ျပီး Class ၃ မိ်ဳးခဲြျခားထားသည္။

1. Class AA (Formerly 1/3B) = ±(0.1+0.0017*t)°C or 100.00 ± 0.04Ω at 0°C

2. Class A = ±(0.15+0.002*t)°C or 100.00 ± 0.06Ω at 0°C

3. Class B = ±(0.3+0.005*t)°C or 100.00 ± 0.12Ω at 0°C

ထို႔အျပင္ IEC တြင္မပါ၀င္ေသာအမိ်ဳးအစားတခုရိွေသးသည္။

Class 1/10B = ±1/10 (0.3+0.005*t)°C or 100.00 ± 0.012Ω at 0°C

ဥပမာ ClassA ဧ။္ tolerance သည္ Temp 100'C တြင္±0.35'C ရိွသည္။

အသံုးျပဳမည့္ေနရာကို လိုက္ျပီးသင့္ေတာ္ေသာ Class ကိုေရြးခ်ယ္ပါ။

Labels:

RTD

Monday, 2 July 2012

SOFT STARTER INTRODUCTION

INTRODUCTION

TO SOFTSTARTER

INTRODUCTION

TO SOFTSTARTER

|

Contents

Squirrel

cage motors

Voltage

NEMA Design

Voltage

Power

factor

Efficiency

Speed

Torque

Direct-on-line

start (D.O.L)

Star-delta

start

Frequency

converter

Softstarter

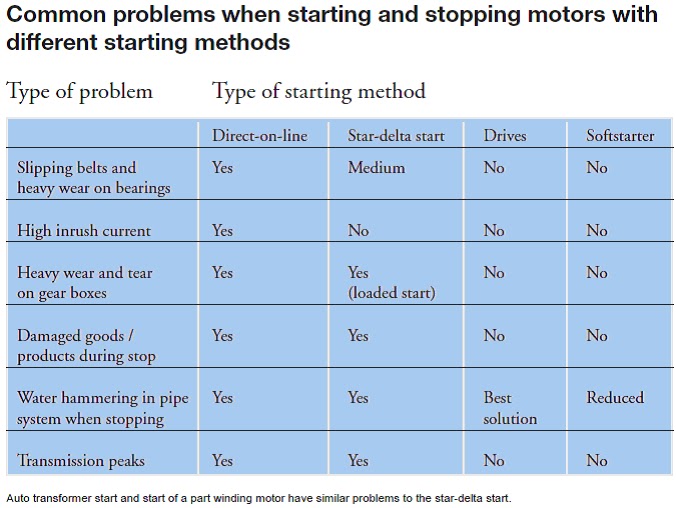

Common problem when starting and stopping motors

Centrifugal fan

Direct-on-line

start (D.O.L)

Star-delta

start

Softstarter

Selection

of a suitable Softstarter

Centrifugal pump

Direct-on-line

start (D.O.L)

Star-delta start

Softstarter

Selection of a suitable

Softstarter

Compressor

Direct-on-line

start (D.O.L)

Star-delta

start

Softstarter

Selection

of a suitable Softstarter

Conveyor belt

Direct-on-line

start (D.O.L)

Star-delta

start

Softstarter

Selection

of a suitable Softstarter

How to select a softstarter

Start

ramp

Stop

ramp

Initial

voltage

Current

limit

Step

down voltage

Adjustable

rated motor current

Parallel

start of motors

Sequential

start of motors

Different ways of connecting the softstarter

In-Line

connection

Inside

Delta connection

Location

of the main contactor

General About Motors

Modern electrical motors are available in many different

forms, such as single phase motors, three-phase motors, brake motors,

synchronous motors, asynchronous motors, special customized motors, two speed

motors, three speed motors, and so on, all with their own performance and

characteristics.

For each type of motor there are many different mounting

arrangements, for example foot

mounting, flange mounting or combined foot and flange mounting. The

cooling method can also differ very much, from the simplest motor with free

self-circulation of air to a more complex motor with totally enclosed air-water

cooling with an interchangeable cassette type of cooler.

Note

that we will focus on asynchronous motors only.

|

Squirrel cage motors

The focus has been

placed on the squirrel cage motor, the most common type of motor on the market.

It is relatively cheap and the maintenance cost is normally low.

Voltage

q Always

refer to motor’s nameplate for termination.

q For

example, use delta connection for 50Hz/380~400 supply volt.

|

|

|

|

|

|

|

|

|

|

|

|

NEMA Design

Three-phase AC motors are classified by NEMA as NEMA A,

B, C and D. NEMA specifies certain operating characteristics for motors when

started by applying rated voltage and frequency (across the line starting). A

NEMA B motor, for example, typically requires 600% starting current and 150%

starting torque.

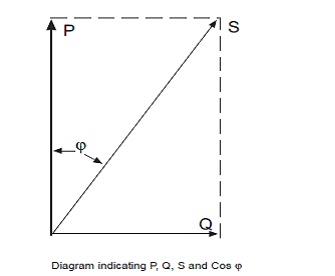

Power factor

q

Ratio between the

active power (kW) and the reactive power (kVA)

q

Designated as the cos j.

q

Normal power factor

value is between 0.7 and 0.9,

q

Small motors have lower

value and large ones have higher value

Efficiency

q Expressed as a percentage.

q Indication of how much input electrical energy is

converted to output mechanical energy.

Speed

Speed

depends:

I. Number of poles of the stator winding

II. Main frequency.

To

calculate the speed of a motor the following formula can be used:

n = 2 x f x 60

p

n = synchronous speed

f = net frequency

p = number of pole

Example: 4-pole motor running at 50 Hz

n = 2 x 50 x 60 =

1500 rpm

4

This

speed is the synchronous speed and a squirrel-cage or a slip-ring motor can

never reach it. At unloaded condition the speed will be very close to

synchronous speed and will then drop when the motor is loaded.

The difference between the

synchronous and asynchronous speed also named rated speed is ”the slip” and it

is possible to calculate this by using the following formula:

s = n1 - n

n1

s = slip (a normal value is between 1 and 3 %)

n1 = synchronous speed

n = asynchronous speed (rated

speed)

Torque

q Torque is a twisting or turning force that tends to

cause an object to rotate.

q Starting torque for a motor

differs significantly depending on the size of the motor.

q A small motor, e.g. ≤ 30 kW,

normally has a value of between 2.5 and 3 times the rated torque

q A medium size motor, say up

to 250 kW, a typical value is between 2 to 2.5 times the rated torque.

q Really big motors have a

tendency to have a very low starting torque, sometimes even lower than the

rated torque. It is not possible to start such a motor fully loaded not even at

D.O.L start.

The rated torque of a motor can be calculated using the following

formula:

Mr = 9550 x Pr

Nr

Mr = Rated torque (Nm)

Pr = Rated motor power (kW)

nr

= Rated motor speed (rpm)

Different starting methods

Direct-on-line

start (D.O.L)

q The most common starting method available on the

market.

q The disadvantage is it gives the highest possible

starting current.

q The starting current normal value is between 6 to 7

times the rated motor current but values of up to 9 or 10 times the rated

current exist.

q The starting torque is also very high, and is higher than

necessary for most applications.

q The torque is the same as the force, and an unnecessary high force

gives unnecessary high stresses on couplings and the driven application.

Star-delta start

q

The starting

current is about 30 % of the starting current during direct on line start

q

The starting torque is reduced to about 25 %

of the torque available at a D.O.L start.

q

This starting

method only works when the application is light loaded during the start.

q

If the motor is too heavily loaded, there will not be

enough torque to accelerate the motor up to speed before switching over to the

delta position.

q

Applications with a load torque higher than 50 % of the

motor rated torque will not be able to start using the start-delta starter.

Frequency converter

q By controlling the

frequency, the rated motor torque is available at a low speed

q The starting current is low,

between 0.5 and 1.0 times the rated motor current, maximum 1.5 x In.

q Another available feature is

softstop, which is very useful, for example when stopping pumps where the

problem is water hammering in the pipe systems at direct stop.

q The softstop function is

also useful when stopping conveyor belts from transporting fragile material

that can be damaged when the belts stop too quickly. It is very common to

install a filter together with the drive in order to reduce the levels of

emission and harmonics generated.

Softstarter

q It has thyristors in the

main circuit, and the motor voltage is regulated with a printed circuit board.

q The softstarter makes use of

the fact that when the motor voltage is low during start, the starting current

and starting torque is also low. During the first part of the start the voltage

to the motor is so low that it is only able to adjust the play between the gear

wheels or stretching driving belts or chains etc. In other words, eliminating

unnecessary jerks during the start. Gradually, the voltage and the torque

increase so that the machinery starts to accelerate.

q One of the benefits with

this starting method is the possibility to adjust the torque to the exact need,

whether the application is loaded or not.

q The softstop function can

also be used when stopping conveyor belts to prevent material from damage when

the belts stop too quickly.

Different applications

All

motors are used for starting and running different applications. The different

applications will also result in different load conditions for the motor.

There are two factors to

consider:

1.

Braking load torque, a direct braking force on the motor shaft. To be able to

accelerate, the motor has to be stronger than the load. The accelerating torque

is the difference between the available motor torque and the load toque.

Accelerating torque = Available motor torque – load torque

2. Involved

moment of inertia or flywheel mass will also affect the start. The bigger

inertia the longer starting time for

the same motor.

CENTRIFUGAL FAN

For

some applications the motor is started with reduced load torque, i.e. unloaded

start. Big centrifugal fans are often started with a closed damper and this

will make the start easier (shorter) but since the moment of inertia is still

present the starting time might be

quite long anyway.

Direct-on-line start

q

Centrifugal fans are very often driven by one or more

drive belts.

q

During a D.O.L start these belts have a tendency to

slip because the starting torque from

the motor is too high during the start sequence and the belts are not able to

transfer these forces.

Star-delta

starter (Y-D)

q Lower starting torque but

depending on the fact that the load torque increases with the square of the

speed,

q The motor torque will not be

high enough in the star position to accelerate the fan to the rated speed.

q

When switching over to delta

position it will be both a high transmission and current peak, often equal to

values when making a D.O.L startor even higher, with a slipping belt as a

result.

Softstarter

q

The key to

solve these problems is to reduce the starting torque from the motor during

start.

q

By using an

softstarter the voltage is decreased to a low value at the beginning of the

start, low enough to avoid slip but high enough to start up the fan.

q

The softstarter

provides the ability to adjust to fit any starting condition, both unloaded and

fully loaded starts.

Selection of a suitable softstarter for centrifugal fan

Normal start

For

fans with small or medium large flywheels, select a softstarter according to

the rated motor power. The above is valid if the time for D.O.L start is less

than 5 seconds.

Heavy duty start

For

fans with large flywheels, select a softstarter designed for heavy duty start

according to the rated motor power. It is also possible to select a softstarter

for normal start, select a unit with one size bigger power rating than the

motor and use an overload relay class 30.

The

above is valid if the time for D.O.L start is more than 5 seconds.

CENTRIFUGAL

PUMP

There

are a lot of different types of pumps; like piston pumps, centrifugal pumps,

screw pumps etc. But the most common version is the centrifugal pump and we

have selected this one to describe.

Direct-on-line start

q

Wear and tear

depending on pressure waves in the pipe system created when the motor starts

and stops too quickly.

q

During a D.O.L

start the motor gives much too high starting torque with the result that the

motor accelerates and reaches nominal speed too quickly. The reason is that the

braking load torque is low for a pump during start.

Star-delta starter (Y-D)

q It is possible to reduce the

starting torque but the motor torque in the star position is too weak to be

able to complete the start and reach the rated speed.

q When the motor reaches

approx. 80-85 % of the rated speed and the switch over to the delta position

will give both high transmission and current peaks with pressure waves as a

result.

q When stopping a pump, it is also normal to have problems. When making a

direct stop by disconnecting the main supply the motor stops too quickly.

Depending on high mass flow in the pipe system the water will continue with the

same speed for a short period and then come back again, backwards in the pipe

system. This creates high pressure shocks on valves and gives high mechanical

stresses on the pipe system.

Softstarter

q

By using an softstarter the voltage is reduced during

the start sequence with the result that the motor torque is reduced. During the

start sequence the softstarter increases

the voltage so that the motor will be strong enough to accelerate the pump to

the nominal speed without any torque or current peaks.

q

During the stop

sequence the softstarter reduces the voltage via a voltage ramp and the motor

becomes weaker and weaker. Because of this the water speed slows down very

smoothly without creating any pressure waves.

Selection

of a suitable softstarter for centrifugal pump

Normal start

Starting a pump is a typical

normal start condition.

Select a softstarter

according to the rated

motor power.

Heavy duty start

Not applicable for this

application.

COMPRESSOR

Smaller compressors are often of piston type and the load torque increases linearly with the speed. Screw compressors are often used when there is a bigger need for air flow and this type has a load torque increasing with the square of the speed.

Direct-on-line

start (D.O.L)

q

Compressors

started direct-on-line are exposed to high mechanical stresses on the

compressor itself, but also on drive belts and couplings. The result is

shortened endurance. In cases where the drive belts are used the belts very

often slip during start.

q

The

high starting torque received during starting with this method is the source of

the problems. The starting current is always high at D.O.L start. A normal

value can be approx. 7 times rated motor current.

Star-delta starter (Y-D)

q

Star-delta

start gives a lower starting torque and starting current but the motor is too

weak during the start up to be able to accelerate the motor up to nominal

speed. When switching to the delta position both current and torque peaks will

occur with high mechanical stresses as a result.

q

Compressors

are very often running at no load condition for longer periods when the

pressure in the system is high. A motor running under these circumstances

always has a poor power factor and low efficiency. Some times the value is so

low that it must be compensated.

Softstarter

q

By

using an softstarter it is possible to limit the starting torque to a level

suitable for all different applications. The result is less stress on

couplings, bearings and no slipping belts during start. The maintenance cost

will be reduced to a minimum.

q

When

using a softstarter the starting current received is approx. 3 to 4 times the

rated motor current.

Selection of a suitable softstarter

Normal start

For

compressors with D.O.L starting time less than 5 seconds, select a softstarter

according to the rated motor power.

Heavy duty start

For

compressors with D.O.L starting time more than 5 seconds, select a softstarter

designed for heavy duty start according to the rated motor power. It is also

possible to select a softstarter for normal start, select a unit with one size

bigger power rating than the motor and use an overload relay class 30.

CONVEYOR

BELT

It is a typical constant torque load with low

to high braking torque depending on how heavy it is loaded.

Direct-on-line start (D.O.L)

q

Conveyor belts

often need a starting torque very near or just above the rated torque of the

motor.

q

A direct-on-line start with a normal squirrel cage

motor gives approx. 1.5 to 2.5 times rated torque of the motor depending on

motor size, type etc.

q

When making a direct-on-line start there is a very high

risk of slipping between the belt and the driving role depending on this high

starting torque. Gearboxes and couplings are also exposed to

high mechanical stresses. This result is considerable wear and tear and often

high maintenance costs. Sometimes fluid

couplings are used to reduce the transferred torque. This method is expensive

and requires a lot of maintenance.

Star-delta start

q It is not possible to use this starting method when

the load torque is close to the rated motor torque.

Softstarter

q By using an softstarter the

starting torque can be reduced to a minimum value still able to start up the

conveyor belt. The setting possibility of the softstarter makes it possible to

adjust the torque to exactly the level that is necessary for the start. The

result is the least possible stress on gearboxes and couplings and no slipping

belts during start. This will reduce the maintenance cost to a minimum. When

using a softstarter you will receive approx. 3 to 4 times rated motor current

during start.

Selection of a suitable softstarter for conveyor belt

Normal

start

A start of short and light loaded conveyor belt is a

typical normal start. For conveyors with D.O.L starting time less than 5 seconds, select a softstarter according

to the rated motor power.

Heavy duty start

Conveyor

belts can in some cases be very long and if the belt is fully loaded during

start the starting time can be very long. For such applications select a

softstarter designed for heavy duty start. It is also possible to select a

softstarter for normal start if the softstarter is chosen one size larger than the rated motor power and

use an overload relay class 30.

How to select a softstarter for

different applications

Selecting

Schneider’s Alistart 01 softstarter for 4KW,400V,3phase

Note

that control voltage must be specified for some other brand of softstarter.

|

Description of the softstarters

Printed circuit board is

used to control the firing of the thyristors based on the current and voltage

references, and also for the calculation of different values, for example the

power factor, active power, etc. It can also be used for storing historical

data, the event log, indicating trends and much more.

Heat sink is used to get rid of the

heat in the softstarter generated by the current during the start and the

continuous run. The capacity of the heat sink very much reflects the starting

capacity and the operational current of the softstarter.

|

Fans are used to increase the cooling capacity of the heat sink.

Some smaller softstarters don’t have fans at all.

Housing can be made of plastic

material, metal or a combination of these, and its function is to protect the

inside components from mechanical and electrical damage. For total outside

protection from dust and dirt a separate enclosure is often required since the

degree of protection (IP class) of the unit itself is too low.

Thyristors are semi-conducting

components connected in an anti-parallel fasion and placed in two or three

phases of the main circuit. They regulate (by increasing or decreasing) the

level of voltage during start and the stop ramp, as described in the picture

below. During a continuous run the thyristors are conducting fully.

Start: The thyristors let part of the voltage through at the beginning and then

increase it, according to the set ramp time for the start.

Stop: The thyristors are fully conducting and when soft stopping, they

decrease the voltage according to the set ramp time for stop.

SOFTSTARTER COMMON SETTINGS

|

|

|

|

|

|

|

|

Aucom CSXi

softstart parameter setting

Aucom CSX parameter setting

Start ramp is the time from were the

softstarter start its ramp (initial voltage) until full voltage is reached. The

ramp time should not be too long, as this will only result in unnecessary

heating of the motor and a risk of the overload relay to trip. If the motor is

unloaded the start time for the motor will probably become shorter than the set

ramp time, and if the motor is heavily loaded, the start time will probably

become longer.

Stop ramp is used when a soft stopping

of the motor is required, for example a pump or a conveyor belt. The stop ramp

is the time from full voltage until stop voltage (initial voltage) is reached.

If the ramp time is set

Initial voltage. Sometimes named pedestrian

voltage or torque, this is the point from where the softstarter starts or stops

its ramps. The torque of the motor will drop with the square of the voltage and

if the voltage is set too low, for example 20 %, the starting torque will

become 0.22 = 0.04 = 4 % only, and the motor will not start from the very

beginning. Therefore it is very important to find a level that is just high

enough to make the motor take off directly to avoid unnecessary heating.

Current limit can be used in applications

where a limited starting current is required, or at a heavy-duty start when it

is difficult to achieve a perfect start with the setting of the initial voltage

and the start ramp only. When the current limit is reached, the softstarter

will temporarily stop increasing the voltage until the current drops below the

set limit, and then continues ramping up to full voltage.

Note that this feature is

not available on all softstarters.

|

Step down voltage gives a special type of stop

ramp. It is possible to adjust the voltage to drop to a level where the speed

of the motor starts to reduce immediately at the stop command. For low loaded

motors the speed will not reduce until a very low voltage is reached, but using

the step down voltage function can eliminate this phenomenon and is especially

useful for stopping pumps.

Adjustable rated motor

current makes

it possible to set the motor rated current on the softstarter for the used

motor. This setting may affect other values as well, such as the trip level of

the electronic overload relay, the level of the current limit function and so

on.

Derating when used above Ambient temperature

Above

ambient temperature recommended by manufacture, the following formula can

generally be used to calculate the operational current:

Ie derated = Ie - (Δ T x Ie x 0.008)

Ie derated = maximum operational current after derating

Ie = rated current of the softstarter

Δ T = temperature difference

0.008 = derating factor

Derating when used at high altitudes

% of Ie = 100 -

x - z

150

x = actual altitude for the softstarter

z = manufacture’s recommended

altitude

Start of several motors

Parallel start of motors

There

are two important parameters to check:

1.

The softstarter must be able to cope with the rated current for all motors

together.

2.

The softstarter must be able to cope with the starting current for all motors

together until rated speed is achieved.

Note! If a by-pass contactor is used for the

softstarter, only point 2 above has

to be

taken into consideration.

|

Example:

Start

of two motors with Ie = 100 A and

relative

starting current 4 x Ie.

Starting

time is 10 seconds.

Total

starting current is 100 x 4 x 2 = 800 A

over 10 seconds.

|

|

|

||||

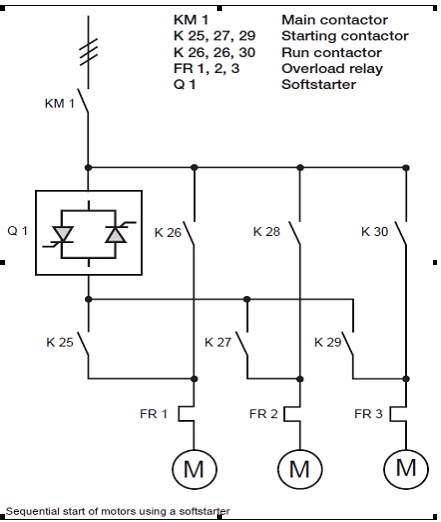

Sequential start of motors

Example:

Start of three

motors with Ie=100 A and relative starting current 4 x Ie.

Starting

time for the motors is:

Motor

1 = 5 seconds

Motor

2 = 10 seconds

Motor

3 = 8 seconds

The

starting current for the motors is 100 x 4 = 400 A and the total starting time

is 5 + 10 + 8 = 23 seconds.

Note! It is not possible to add the starting time for each motor if

the rated current is different from one motor to another. A separate

calculation has to be made for those applications.

|

Different ways of connecting the

Softstarter

In-line connection

q The most common way to

connect the softstarter. The selected devices for Inline connection must be

chosen to cope with the rated motor current.

Example: 100 A motor requires a 100 A

softstarter, 100 A main contactor etc.

Inside Delta connection

q The Inside Delta connection

makes it possible to place the softstarter in the delta circuit and in that way

it can easily replace an existing Y/D-starter. When the softstarter is Inside

Delta it will only be exposed to 58 % (1/√3) of the In-line current. Therefore

it is possible to downsize the devices in order to achieve a more

cost-effective solution.

Example: A 100 A motor requires a 58 A softstarter, a 58 A main contactor if

placed in the delta

circuit, etc.

q Note that only a few types

of softstarters can actually be connected Inside Delta.

Location of the main contactor

q When using the softstarter

Inside Delta there are two options for the main contactor: in the delta circuit

or outside. Both locations will stop the motor but in alternative A, the motor

is still considered to be under tension.

q In alternative B the main

contactor must be chosen according to the rated current of the motor, while the

contactor in alternative A can be chosen according to 58 % (1/√3) of the rated

current.

Basic settings for different

Applications

Note ! All settings below are only proposals and may change from one

application

to another and therefore need to be checked individually.

|

Frequently asked questions (FAQ)

Main contactor

Q Is

there any requirement to put a main contactor in series before the softstarter?

A The

softstarter does not require any main contactor but we recommend the use of one

for emergency stop and/or trip of the overload relay. In some applications an

MCCB can be used instead of the main contactor.

Advantages of by-pass

Q What

are the advantages of using by-pass?

A Reduction

of power loss. It is also possible to reduce the enclosure size and use a

higher IP-class since air ventilation is not required.

Test without motor

Q Can

I test a softstarter without using a motor?

A No,

this is not possible since there will be no current going through the

softstarter and some types will also indicate loss of load.

Different frequency

Q Can

I use the same softstarter at both 50 and 60 Hz?

A It is possible with all type of ABB softstarters as

long as the curve is sinusoidal.

Overload relay trips during start

Q Why

does the overload relay trip during start?

A Possible

reasons can be one of these or in a combination:

- too low current limit

- too long ramp time

- too low initial voltage

- wrong tripping class on the overload

- wrong setting on the overload

Voltage fluctuations

Q What

voltage fluctuations are allowed for the softstarters?

A The

minimum and maximum value where we can guarantee full function is -15 % to +10

% of the rated value. This is also stated in the IEC-standard.

Example:

400 V - 15 % to +10 % ≥ 340 V - 440 V range

Labels:

Motor Control

Subscribe to:

Comments

(

Atom

)